Model | GC1530P GC1540P GC2040P |

Working area (X-Y) | 1500mmx3000mm 1500*4000mm 2000*4000mm |

Working material | Iron, Steel, Aluminum sheets, Galvanized sheets, Titanium Plates |

Working Thickness | 0.5-40mm |

Cutting Speed | 0-8000mm/min |

Power | 15kw |

Input Voltage | 380V 50HZ (or according to your need) |

Plasma Current | 63A/100A/120A/160A/200A/300A |

Connecting Way | USB |

Working Mode | Untouched arc striking |

Cooling method | With water pump and tank provide circulating water cooling |

Z axis travel | 0-70mm |

The automatic elastic raise | 0-5mm |

Rail guide | Precision work round |

Transmit way | Taiwan imported ball screw |

Operation language | English (Option) |

Command | G code, *uoo, *mmg, *plt |

Optional power source | USA brand Hypertherm powermax 45 65 85 105 125 200 |

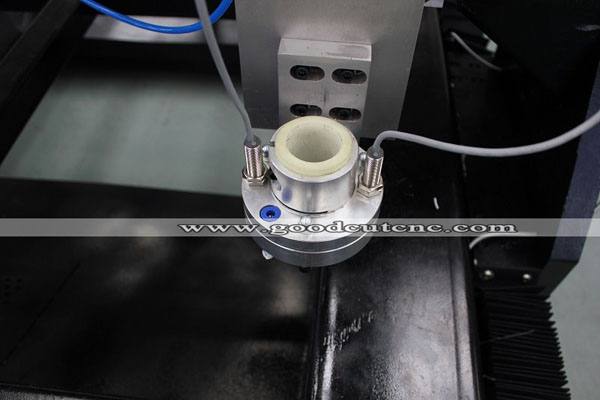

Spare parts | Electrode ,Electricity nozzle and Water jacket

|

Features

1. Welded structure of thickening square tube, together with top brand guide rail to ensure high running speed and accuracy.

2. Hypertherm plasma power supply together with high sensitive arc pressure adjuster. Self-adjusting can choose the best distance between plasma gun and working piece automatically to ensure high accuracy cutting.

3. CNC pasma cutter for sheet metal uses STARFIRE control system with FastCAM software for auto material saving function, large capacity storing function, convenient to read and process.

4. Cutting head with cooling system can quickly cool surface of material to avoid burr and residue.

5. Overall stepper motor with high precision rack and pinion, to ensure the cnc plasma cutter has small noise, smooth, precise coordinates of the mobile performance.

6. Perfect software compatibility, such as Ucancam, Type 3, Artcum, etc.

Buyer's Guide

A computer-controlled CNC plasma cutter will always be a significant investment because of the higher budget you will have to pay for the machine. Therefore, selecting the right one is crucial to enhance the quality of your work. Some of the key factors that will help you to choose the perfect tool have been discussed below.

The first thing comes first. The cutting capacity is always a crucial factor with such kinds of machines. The tool should have a better capacity to cut the metals with precision. If you are working with thick metals, ensure that the machine you are about to buy can handle that much thickness. Additionally, consider the maximum cutting speed of the machine and how it will affect your productivity. Precision, software, maintenance, maneuverability, and pricing are some of the other factors that should be considered while purchasing such a tool. Last but not the least; consider the level of support and service provided by the manufacturer. Look for a manufacturer that offers excellent customer support, including technical assistance, training, and ongoing maintenance.

The continuous progress of CNC automation and plasma cutting technology has made the types of CNC cutters more and more abundant, and the market's requirements for metal processing quality have also been continuously improved. There are options from 63A to 200A, with large format and small table, precision cutter, pipe cutter, plate and tube integration. They have become a hot-selling metal processing and forming product in recent years.