Parameter:

Item | Parameter |

Laser source | Nd3+: YAG |

Max. Laser Power | 240w |

Single-pulse energy | 90J |

Pulse Width | 0.1-20ms |

Wavelength | 1064nn |

Frequency range | 0-50Hz |

Welding pool diameter | 0.3-1mm |

Facula diameter | 0.1-3mm |

Observing system | Microscope |

Chamber illumination | LED lamps |

Shield gas supply | One Line |

Cooling | Water cooling |

Power consumption | 5.5kw |

Power supply of laser | 220V /50HZ |

Power supply of chiller | 220V/50HZ, 1HP |

Running environment | 5℃-30℃ 5%-75% humidity |

Net weight | 110kg(welder)+50kg(chiller) within |

Feature:

1. Imported ceramic concentrating cavity, high reflectivity, strong energy, high temperature resistance, corrosion resistance and long service life.

2. The laser energy, pulse width, and frequency are adjustable, suitable for precision welding of various metal micro-small parts and jewelry;

3. The internal space is large, which is convenient for the placement of laser spot welding tools and fixtures; the welding debris recovery box is installed for easy cleaning and gold welding slag recovery.

4. LED ring-shaped shadowless lamp, observing the workpiece without shadow, with the high-definition parallel light path microscope, the laser welding position can be observed more clearly.

5. High-power beam expansion system to obtain a finer light spot to meet the needs of fine laser spot welding.

6. The protective gas output by the laser synchronously ensures that the solder joints are beautiful without oxidation and discoloration.

7. The whole machine conforms to ergonomic design, which is more suitable for the jewelry industry, with stable performance and suitable for long-term continuous work.

Application:

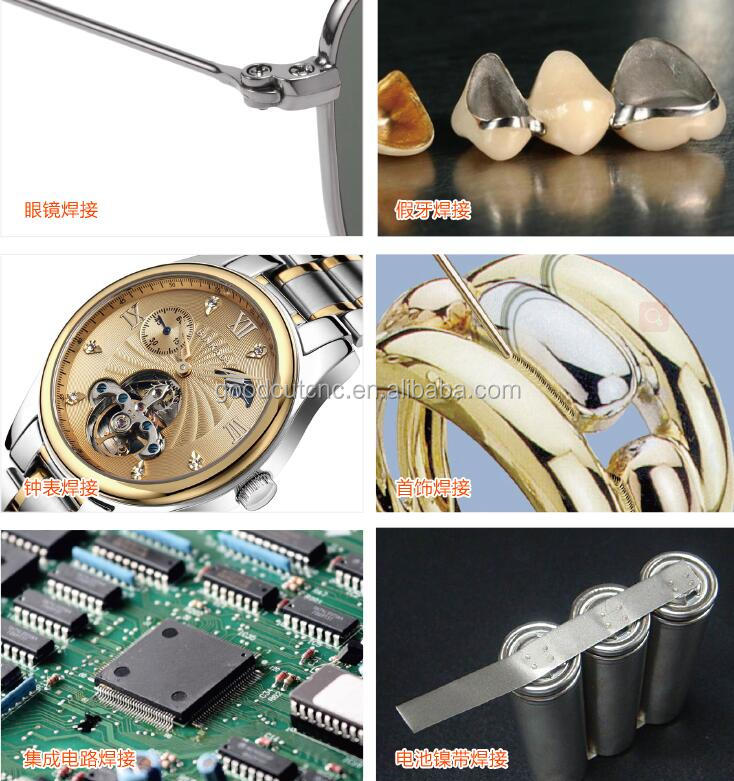

Widely used in precision casting welding, such as:

jewelry, dentures, clocks and watches, medical, instrumentation, electronics, mechanical mold processing, automobiles and other industries.

It is especially suitable for the welding of gold and silver jewelry's repair holes, spot welding sand holes, repair seam patterns, inlaid parts and claw feet.

Definition

A laser welding machine is an eco-friendly power welding tool with a handheld laser gun, CNC controller, or single-arm robot to join pieces of metals or thermoplastics. Laser beam provides a concentrated heat source, which is used for spot welding, butt joint, lap joint, lap edge, lap, T butt, seam welding, narrow welds, deep welds, and kissing weld with high rates. The process is frequently used in high volume applications with automation, which is based on keyhole or penetration mode welding. Laser welders are engine driven welding machines used for a variety of applications from joining very small parts together commonly used by manufacturing businesses in the engineering, medical and electronics industries, through to welding thicker materials in the automotive and aerospace industries. A laser welding machine is also known as laser welder, welding gun, welding tool, seam welding machine, bonding machine, brazing machine, joining machine, soldering machine.

Types

Laser welding is a versatile, low cost way of achieving high quality spot welds for different materials and thicknesses. It results across a wide range of materials. There are three common types, including CO2, YAG and fiber laser welders. There are high-power welders for large-format and thick sheets, and low-power welders for small-size parts.There are welders for metals and non-metallic materials such as plastics and ceramics.

Different methods can be classified as follows:

• Welds between slices. Including butt welds, end welds, center penetration fusion welds, and center perforation fusion welds.

• Wire and wire welds. Including wire-to-wire butt welds, cross welds, parallel lap welds, and T-type welds.

• Welds of metal wires and block components. It can successfully realize the connection between the metal wire and the block element, and the size of the block element can be arbitrary. Attention should be paid to the geometric dimensions of the wire-like components during welding.

• Welds of different metals. Welds different types of metals must solve the range of weldability parameters. The welding between different materials is only possible with certain material combinations.