Advantages

1) Realizing Multi-function: this machine was designed with HSD aggregate

head to realize multi function.

2) Improving working efficiency: Designed with linear tool change magazine to promote the working efficiency. Various of tools can be changed automatically in the engraving process.

3) In addition to the typical application of ATC CNC machines, the machine can also be used for milling, boring and drilling.

4) Supporting customized services: The machine’s working size can be made to larger or smaller; Rotary device can be added on the CNC Machines; The spindle is allowed for swing 180 degree to carve three-dimensional objects and molds.

5) Please notice that all the specifications of machine can be designed and made according to your own actual requirements.

Linear tool magazine, with Tool holders x 6pcs and Toolholder fork x 8 pcs, effectively improve working efficiency.

C aixs Italian HSD atc spindle, can rotated

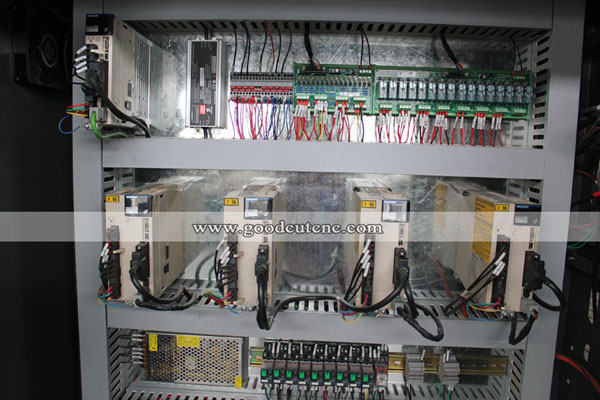

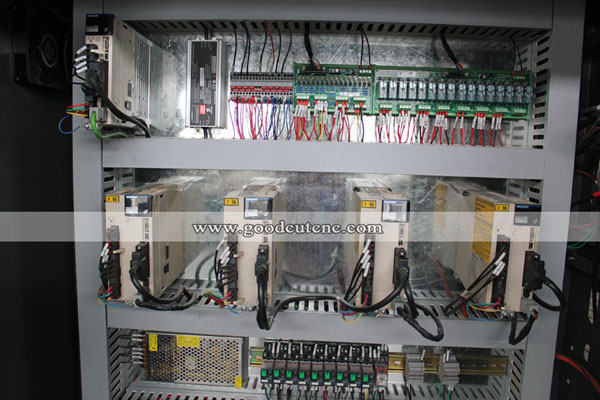

Japan Yaskawa servo motor and driver, powerful and high precision.

Control system: Syntec 6MB controller

NO. | Description | Parameter |

1 | X,Y,Z Working Area | 1300x2500x200mm |

2 | Table Size | 1300×2500mm |

3 | Spindle | Italy HSD951 9Kw air cooling spindle with C axis Auto tool change |

4 | Operating System | Taiwan Syntec 60W-E control system |

5 | Motor | Japan Yaskawa 850w servo motor C axis 400w |

6 | X, Y Structure | Rack and Pinion Drive, Hiwin Rail Linear Bearings 30mm |

7 | Z Structure | Hiwin Rail Linear Bearings and Ball Screw |

8 | Tool magazine | Linear tool changer, 10pcs Include 2 pcs angle head tool holders |

9 | Tool shaft | HSD manual adjustment Angle saw blade milling cutter dual purpose tool shaft |

10 | Table | Vacuum table, 8 pcs adsorption |

12 | Vacuum pump | 7.5kw vacuum water cooling pump |

13 | Dust collector

| 5.5kw dust collector

|

14 | Inverter | Delta inverter |

1. Gantry moving design, Y-axis dual motors with precision grinding helical gear transmission to ensure the accuracy of the machine;

2. Equipped with high-precision HSD 9KW ATC tool change spindle, rotating speed 24000rmp/min, save time and avoid manual tool change error;

3. Adopted whole set YASKAWA servo motors and drivers, working speed up to 28000mm / min;

4. Automatic tool sensor, precision tool setting, practical and convenient;

5. Taiwan professional SYNTEC/NK260 Control system with hand wheel, easy to operate and control;

6. Dry rotary vane vacuum pump, power 7.5KW plus vacuum table section design makes the smaller material can be processed at any time.