GC1325ATC GoodCut Linnear Atc Cnc Router with Tool Changer for Kitchen Cabinet Door Making

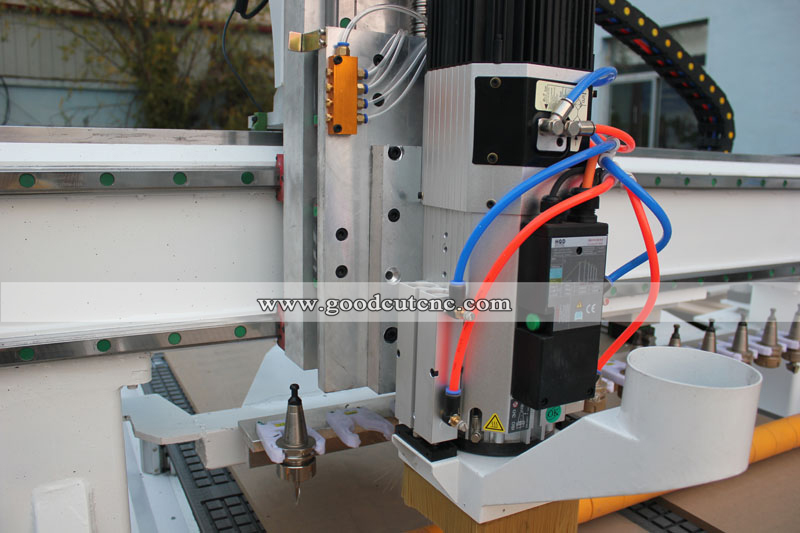

ATC CNC router is a type of smart CNC machine with automatic tool changer spindle kit. ATC is refer to Automatic Tool Changer, the ATC spindle usually carries a tool magazine of 6 cutters or 8 cutters or 10 cutters or 12 cutters. The CNC router tools can automatically change according to the working requirements when the CNC router works, no need of manual operation, with good starting performance and large torque, it can give full play to the advantages of the machine's high speed and higher efficiency. It adopts high-torque servo motor made in Japan, which has the advantages of low noise, high speed and high positioning accuracy. Equipped with a unique tool-changing mechanism, you can exchange the required tools at will, and the dedicated tool setting table can accurately compensate the tool length error. The tool change time only takes a few seconds, which will improve the working efficiency greatly. There are two most common types ATC CNC machines, which includes linear type automatic tool changers and rotary type automatic tool changers. The best ATC CNC router machine adopts a rotary 4th axis for 3D cutting and carving.

Feature:

1) Ncstudio control system: Popular and easy operation, with USB port to transfer program;

2) China Local Brands HQD air-cooling ATC spindle: Long working life, easy maintenance;

3) Taiwan Delta Servo Driving System: With highly control precision and high speed, reliable and stable;

4) Taiwan Hiwin Guide and Block: Guaranteed genuine rail with good quality,realizing smooth movement;

5) Taiwan TBI ball screw: linear motion with high precision and and in high speed

6) Helical rack and pinion: quiet running, greater accuracy, smoother cutting and allows greater accelaration and feeding rates, longer lifetime because of smaller wearing force.

7) Taiwan Delta Inverter: Guarantee the variety working speed and protect the spindle very well;

8) Linear tool magazine, with Tool holders x 6pcs and Toolholder fork x 8 pcs, effectively improve working efficiency.

| |

| |

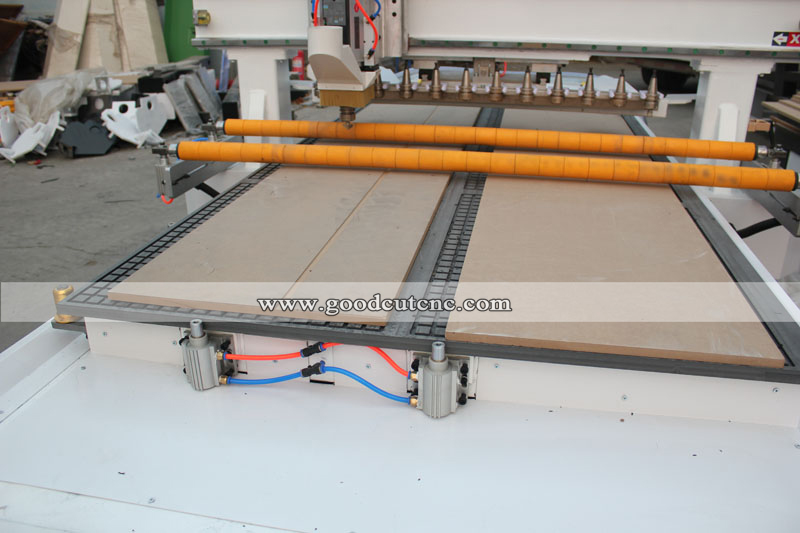

| Vacuum with T-slot Table , 7.5kw big power vacuum pump |

| |

| 25mm 30mmHIWIN linear guide, helical rack |

| Hiwin Rail Linear guide and TBI Ball Screw |

| (Without Spindle)2.5kw~3kw |

| 9kw HQD or Italy HSD air cooling spindle |

| |

| 850w Leadshine servo motor driver |

| AC380V/50-60Hz,3PH (Option: 220V/1phase) |

| |

| |

| 11kw DELTA inverter or Fuling |

| |

X,Y,Z repositioning Accuracy | |

| |

| Type3/UcancameV9 Software, (Option: Artcam Software) |

| |

| |

| 5.5kw double packages dust collector |

| |

| Japanese YASKAWA servo motor, Syntec 6MB controller Rotary device |

4x8 ATC CNC Router Machine Applications

1. Woodworking Industry: Stereo wave board processing, wooden door, cabinet making and other furniture production.

2. Advertising Industry: Label making, PVC plate, PCB board (drilling and engraving), double color boards, logo production, acrylic cutting, plastic suction for making advertising dedication, word cutting, sign making, crystal word, LED display screen, doorplate, nameplate, etc.

3. Mold Industry: Wood mold, foam mold and metal mold, etc.

4. Musical instrument industry: Instrument 3D surface carving, shape cutting5. Woodcrafts.6. Exhibition industry: Showcase.

1. Furniture industry: solidwood doors, composite doors, cabinet doors, interior doors, sofa legs, headboards, antique furniture and superficial flower-shaped engraving of various plate-type furniture and disposable finishing of process.

2. Decorated industry: variety of decorations engraving process such as decorative murals, screens, decorative patterns, three-dimensional wave boards, sound-absorbing panels and so on.

3. Advertising industry: engraving and making for acrylic cutting and engraving, acrylic plastic model making, badges and a variety of logo signs.

4. Arts & crafts industry: sculpture making of arts & crafts such as process relief, shadow carving, craft ornaments, car accessories and so on.

5. Musical instrument industry: headstock processing ,guitar semi-finished products processing, surface sculpture and three-dimensional curved surface making of various musical instruments' decorative patterns.