Advantage:

*Easy to learn and operate

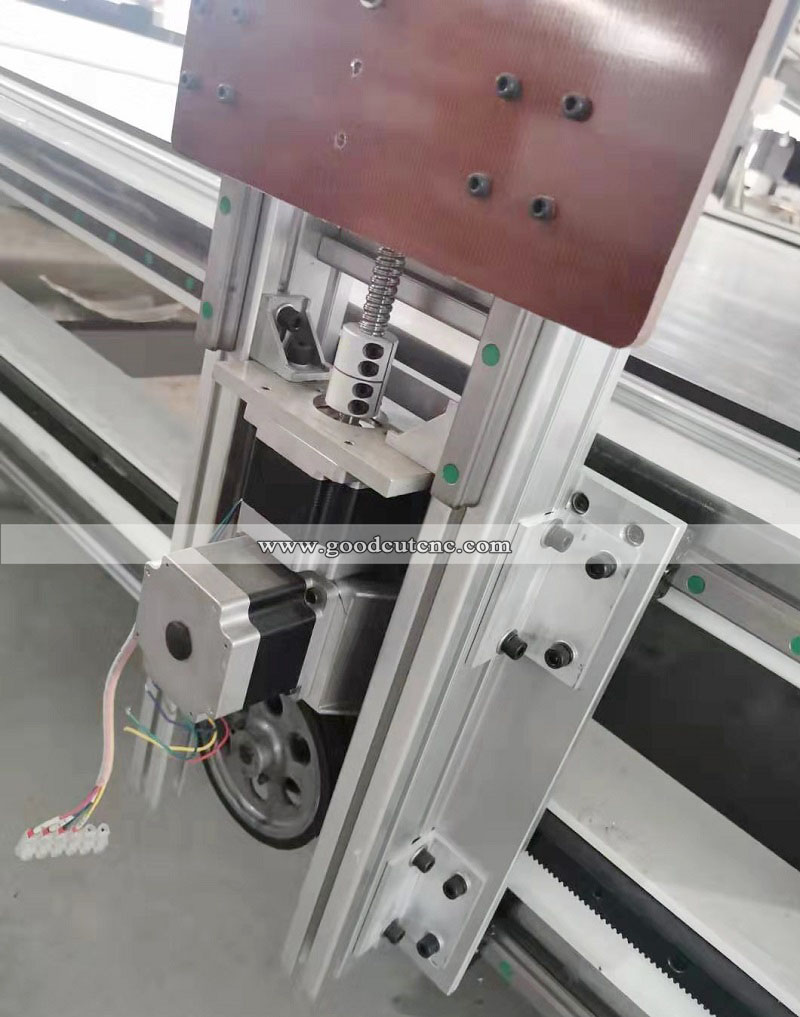

*TBI ball screw transmisson with high efficiency

*Adopt all English language system and software

*without noise when processing materials

1. CNC cutting machine is controlled by the computer system, and we can design and make the different kind of cutting machine according to the different products requirements, it can save a lot of the cost such as replace the mould and save a lot of time. It used for a lot of yields especially on the packing industry.

2. GoodCut hot wire 3D cuter is a special cutting machine which for complex shape product of EPS. This kind of cutter has one or several cutting lines for different production request.

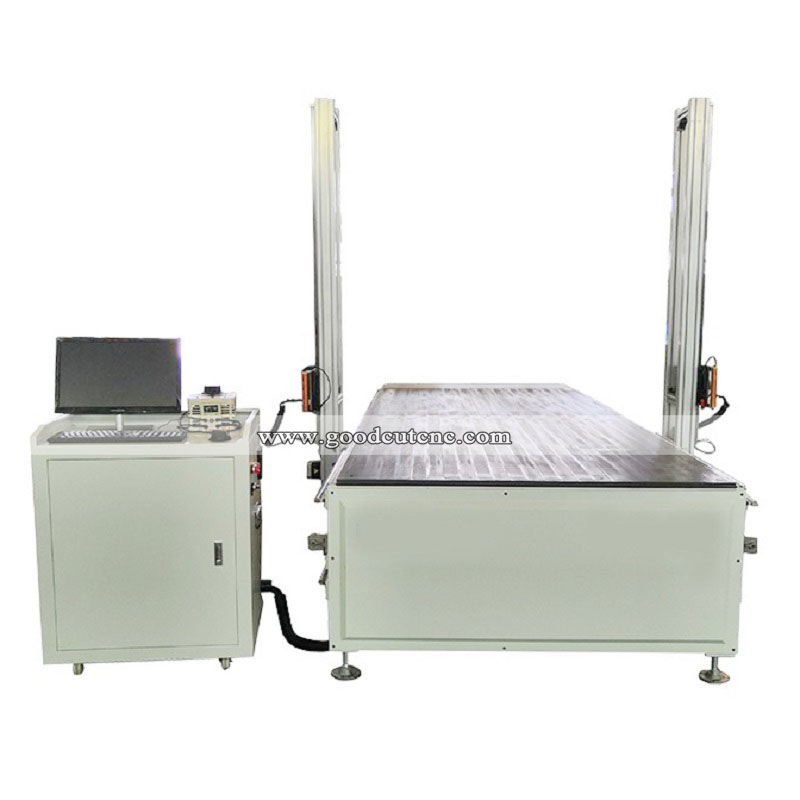

GC1330F hotwire foam cutter Description & Specifications: |

X Working Area | 1300mm |

Y Working Area | 3000mm |

Z Working Area | 1300mm |

Traveling Positioning Accuracy | ±3mm |

Repositioning Positioning Accuracy | ±2mm |

Working dpi | ±0.04mm |

Rotating Speed | 0-6000mm/min |

Machine Structure | Thick welded steel |

Command | G-code*.u00*.mmg*.plt |

Working voltage | AC220V/20HZ |

Weight with package | 850kgs |

Package size | 1.6(width)*3.8(length)*1.5(width)m |

Control System | dsp |

Guide Rail | Round guide |

Features:

1.Whole steel structure,durable model. dual motor drive, high speed.

2.Professional design software,easy to drawing.

3.DSP or NC studio controller for option.

4.Imported wires(0.3mm diameter) to guarantee the better running.

Hot wire foam cutting machine is controlled by computer,the drawing and cutting software support English and Chinese,easy to operate:the users make drawing in software,then convert into cutting code,the machine will run automatically. Mainly used for: complex 3d design tool symbols, letters, text graphics architectural appearance, architectural decoration components, architectural models, exhibition booths and so on.