Feature:

1.Swiss Raytool brand Auto sensor laser cutting head. With Auto sensor system. Make sure cutting steel which is out of shape.

Inside laser head, with one collimating mirror, one focus lens and protect the mirror. At the bottom with copper nozzle, diameter mainly with 1.5mm diameter.

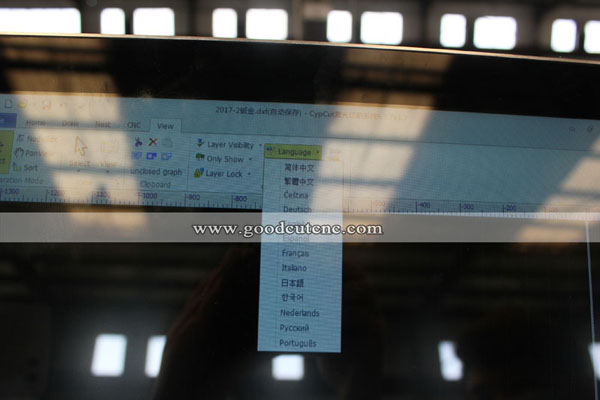

2.With CYPCUT Control system and software with the English language, applicable insert files with DXF Or AI format. Drawing in the software is also okay. Software with fly cutting mode for cutting the same products to save time. With Nesting function, automatic compose type for saving materials by saving spaces.

3. When laser head cut metals, there will produce some hot energy in the laser head and laser source. A water chiller is for cooling the mirrors and cooling the laser source. The temperature in the water chiller is an auto adjustment, mainly set up with 25-degree around water in chiller should be pure water.

4. Chinese best brand Raycus laser device 500W-6000W: Applicable for cut high reflect materials like aluminum and copper. The photoelectric conversion more than 30%, Working environment: 10-40 degrees. Device with air-conditioning to keep it at normal temperature.

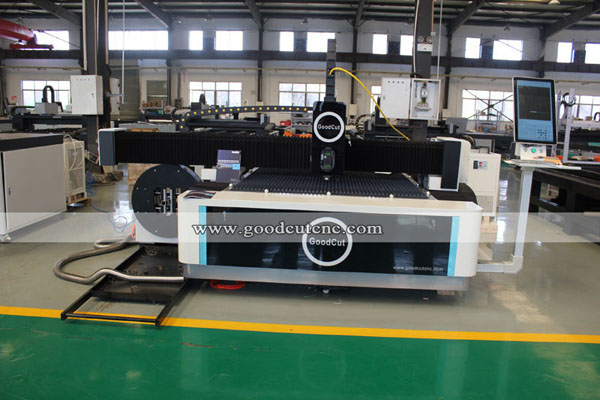

5. Gear- rack transmission system which with Taiwan brand rails. X and Y axis Moving speed can max 80m/min.

6. Big torque Delta drive motors. Match-able with the transmission system, improve cutting speed and precision

7. At the bottom of the machine, with the collector for saving small cutting pieces. Below collector with wheels, easy push and pull.

8. The purging system is designed inside the machine bed. So make sure the smoke is absorbed immediately after cutting. Protect the air environment is also very important.

9. Feeding system with rolls. It is easy to load heavy sheet and metal sheets can be protected by avoiding scratched

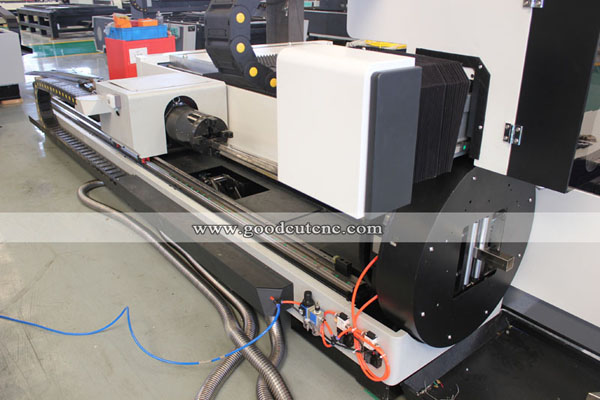

10. Plate and tube fiber laser cutting combination, one machine dual use

11. X-axis beam is aircraft-grade aluminum casting, replace of the welded steel gantry, more light-footed to make the whole machine working very fast.

Parameter:

Items | Parameters |

Model | GC-1530FR |

Laser Source | IPG / Raycus |

Power | 500w 1000w 1500w 2000w 3000w~40000w(can be customized) |

Linear Rial | HIWIN |

Servo Motor | France Schneider Servo System |

Reducer | Japanese Shimpo Reducer |

Cutting Head | WSX / Raytools |

Control System | Cypuct / Weihong |

Wave Lenth | 1080nm |

Cutting Width(X&Y) | 1300*2500mm 1500*3000mm 3000*12000mm (can be customized) |

Laser Media | Fiber Laser |

Voltage Requirements | 220v or 380v/50Hz~60Hz |

Min.Route Width | 0.1mm |

Reposition Accuracy | ±0.05mm |

Aiming Positioning | Red Dot |

Pipe Material Length | 0~6000mm |

Pipe Material Diameter | 10~300mm(Optional) |

PS.All the working area and specifications can be customized according to your requests |

Optional Parts:

1. Raytools laser head.

2. Imported IPG laser source.

3. Japan Yaskawa servo motor and driver.

4. S&A water chiller.

5. Shimpo reducer or MOTOVARIO reducer.

Characteristics:

1, High speed, high precision, high efficiency and low cost

2, Easy on operation, fiber optical path, without tediously adjustment on optical path

3, Compact structure, good sealing, strongly adaptable to changes in the environment.

4, With the perfect automatic nesting system which can save time, save the materials, the sheet utilization ratio up to 95%

Application:

1.Widely used in cutting carbon steel,manganese steel,spring steel,stainless steel,titanium alloy,galvanized sheet,aluminum plate,brass copper and other metal plate material.

2.Used for metal round,square tube,such as carbon steel,manganese steel,spring steel,stainless steel,titanium alloy,galvanized sheet Aluminum plate,brass,copper.

3.Ultra-high type,special metal material cutting.

Sample: