Description:

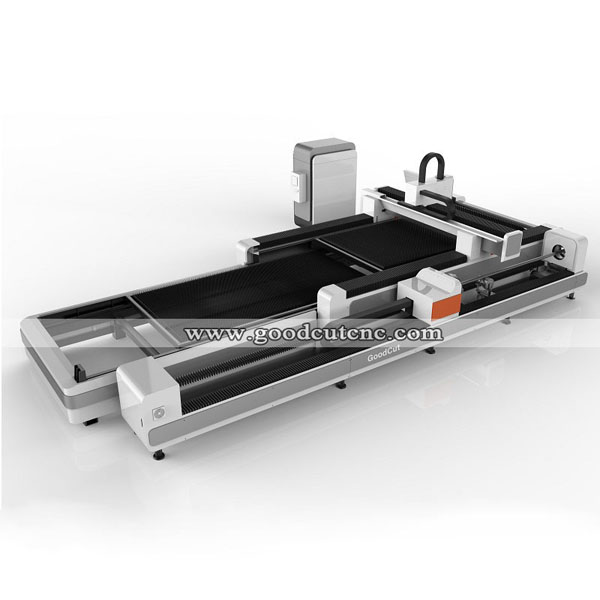

1. This model integrates square tube, circular tube, oblate tube, and plane cutting in one, with multifunction and high practicality.

2. Gantry structure and dual drive, Germany imported rack & pinion drive system. Excellint cutting performance and stability.

3. Selt-centering jig system ensures stable process of conveying pipes, so that it can ensure high accuracy and high quality of products.

4. The machine, with high accuracy of machining dimension, can take the place of traditional processing equipment, such as sawing and punching.

5. Saddle-shaped pipe type support beam is with high precision calibration, no derformation during 6m pipe cutting.

Details:

1. Machine Bed: exchange platform, save time and improve efficiency.

High compressive Strength and high hardness, will not deformation in a life cycle and maintain accuracy for a long time

2. Transmission:

Taiwan HIWIN square guide rails; Taiwan TBI ball screw

Strong and durable, small friction running resistance is small can effectively improve the working speed

3. Laser Cutting Head: Raytools and WSX for optional.

Single and double configuration flying light path design Unique optical structure design light path deviation is small stability direction regulation

4. Laser source: Raycus and IPG for optional.

1). Direct control of all the fiber laser functions;

2). control of the laser source;

3). High speed perforation

4). More than 100,000 hours work-life of pumped diode,almost free maintenance.

5. Control system: Cypcut control system.

Main Parameter:

| Model | GC1530FR-D |

| Working area | 3000*1500mm |

| Miximum length of pipe(Options) | 3000mm(or)6000mm |

Limits of pipe(Customized) | Round tube:Φ20mm~Φ120mm; Square tube :Φ20mm~80mm; Circular tube: Φ20mm~Φ120mm;Square tube: Φ20mm~80mm |

| Laser type | Fiber laser generator |

| Laser power(optional) | 500~2000W |

| Transmission system | Double serve motor &gantry&rack&pinion |

| Maximum speed | ±0.03mm/1000mm |

| Pipe cutting system(optional) | yes |

| Maximum speed | 60m/min |

| Maximum accelerated speed | 0.6G |

| Position accuracy | ±0.15mm/1000mm |

| Reposition accuracy | ±0.02mm/1000mm |

| Graphic format supported | CAD,DXF(etc) |

| Total power | 10KW |

| Power supply | 380V/50Hz/60Hz |

| Overall dimension(include cutting machine in 3 meters long) | 4350mm×3200mm×1740mm |

| Overall dimension(include cutting machine in 6 meters long) | 7650mm×3200mm×1740mm |

| Gross weight | 5000kg |

Application Industries:

Fiber Laser Cutting Machines are widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting, Hardware, Auto Parts, Glasses Frame, Electronic Parts, Nameplates, etc.ensure that it can operate ng possible during the laser cutting process.

Application Materials:

Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring Steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc