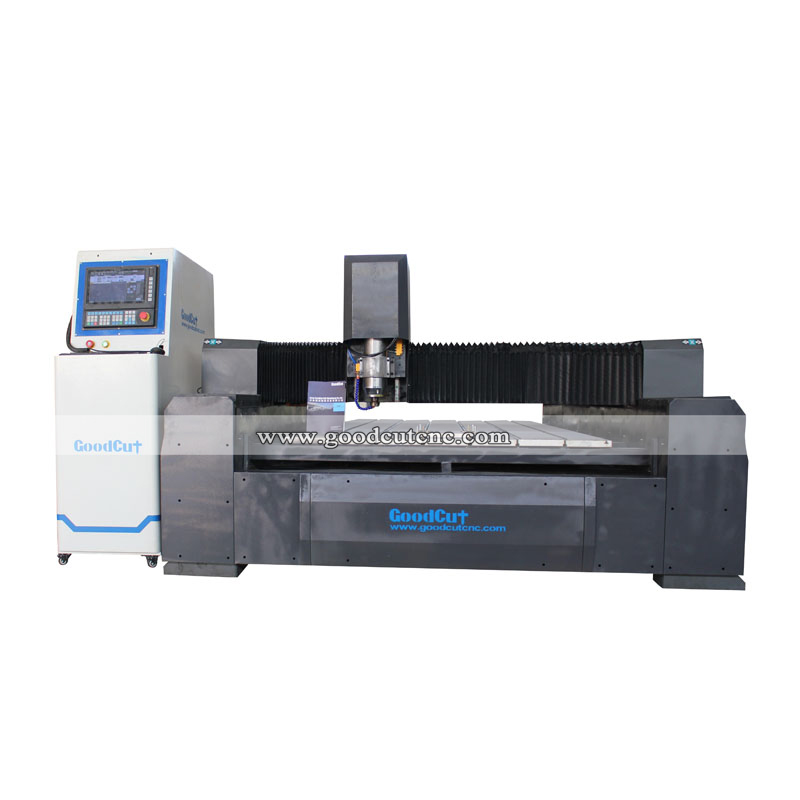

GC1540W New Design Stone CNC Machine for Marble Granite Quartz Metal PVC Woodworking

Looking to buy an affordable stone CNC machine to carve personalized relief sculptures for you custom business, or create 3D Buddha head statues using a rotary attachment as works of art?

Having an idea to get an automatic stone carving machine to make headstones & gravestones in memory of your family and friends, or start a new tombstone business? Need to purchase a 3 axis, 4 axis or 5 axis CNC bridge saw to custom kitchen countertops and bathroom vanity tops to upgrade your home improvement business? Here is the right place for your needs and budget. STYLECNC is the most trusted manufacturer & maker to provide all types hobby & industrial CNC machines for stone carving, engraving, cutting and polishing. You'll get a cost price for your machine tools and free expert customer service & support from GoodCut. Let's start understanding the super practical buying guide to all stone fabricators.

Definition

A stone CNC machine is an automatic power tool with computer numerical controller for hobbyists and industrial manufacturer to make custom stone machining for artwork, decorations, souvenirs, gifts, crafts, tombstones and home improvement. It is capable of carving, engraving, cutting, polishing for basalt, granite, quartzite, limestone, marble, onyx, jade, travertine, alabaster, sandstone, slate, soapstone.

Applications

Stone Industry

Granite, marble, quartzite, slate, sandstone, alabaster, basalt, jade, limestone, travertine, artificial stone, tombstone, headstone, cemetery, and memorial.

Kitchenware

Slate countertops, artificial quartz countertops, artificial marble table top, ceramic tile, and kitchen decorations for sink, oven, cooktop.

Decorations

Stone crafts, gifts, jewelry, wall decoration, building decoration, portrait, Buddha statue, and some exquisite stone arts.

Woodworking

Chair, door, window, bed, cabinet, kitchenware, redwood classical and antique furniture, exquisite european furniture, sculpture.

Mold Making

Copper, aluminum, building models, shoes, badge, embossed mould, biscuit, candy, chocolate mould, artificial marble, plastic, PVC, wood, foam.

Advertising

Billboard, signage, badges, logo, company plate, signs, emblem, badge, display panels, fair signs, building numbers, decoration, 3D character.

1. Professional industrial control full-function system, vibration knife cutting, high-light mini words, cutting edge cutting 3 in 1, powerful, easy to operate.

2. industrial heavy-duty steel structure design, annealing stress removal, and numerical control high-precision pentahedron machining center once processing to ensure the optimal strength and rigidity of the fuselage.

3. Adopt column frame gantry, table moving transmission mode, more stable equipment, less vibration.

4. Standard with professional matrix vacuum adsorption platform, large bearing capacity, optimized zonal management, suitable for all kinds of workpiece processing.

5. Japan servo motor and drivers .

6. Taiwan high precision ball screw transmission, and the precision is higher.

7. X, Y adopt full dustproof design, Z shaft is equipped with main shaft safety protection cover.

8. Adopt the Japan big torque YASKAWA servo system.

9. Independent industrial control cabinet, strong and weak power separation, maintenance more convenient.

10. Adopt 5.5/ 7.5kw water cooling spindle

Parameters of GC1540 Professional Engraving Metal CNC Router Machine For Aluminum Copper:

Features | Parameters | ||

Linear Rail | Configure with Japan THK linear rail 25mm width | ||

Package size | 3460x2280x2080mm, Weight :2800KGS | ||

X,Y working area | 1500*4000mm, machine transmitting by rolling ball screw, high precision. | ||

Z working area | 170mm, Z axis with high precision grinding rolling ball screw. | ||

Max. Moving speeding | 30m/min | ||

Work-holding | Standard with independent 4 zone matrix vacuum table with high strength | ||

Control system | NC/DSP /Mach3 control system, | ||

Spindle motor power | 5.5kw/ 7.5KW water cooling high speed auto tool change spindle motor | ||

Surroundings for software | Windows10/7/XP | ||

Working voltage | AC 380V/50Hz-60Hz (Standard) | ||

Main axis rotating speed | 0-24000rpm/min | ||

Work Mode | servo motor and driver, and Fuling inverter, speed control uniform and cutting edge smooth. | ||

Machine structure | Adopt industrial heavy-duty structure under heat treatment | ||

Dust cover | XY axis adopt totally closed dust cover design, Z axis with spindle protection cover | ||

Software | New version Ucancam, type3 | ||

Warranty | One year without the tools | ||

Optional device | Dust collection system | ||

Parts images

Heavy duty thicker and bigger welded steel tube frame--more stronger

Servo motor and driver

To ensure the transmission stronger and speed higher, cooperate with Shimpo reducer.

Lubrication system of all machine, just one press, easy to operation.

The Oil mist Coolant System is ideal for coolant tools for cutting metal. The unit's micro-dispenser delivers a very small amount of high-performance vegetable-based lubricant to the cutting tool by atomizing the lubricant in a high-velocity air stream.

Applications of GC1540 Professional Engraving Metal CNC Router Machine For Aluminum Copper:

Advertisement characters etc.

Other industrial: building models, plastic and solid wood models, three-dimensional surface processing of musical instruments, electronic industry , woodworking furniture, cabinet door panels, building materials processing etc.

It also applies to engraving and cutting on copper, aluminum and iron plates.

This series of products are more focused on high precision processing model, suitable for advertising, electronics, woodworking, furniture, aluminum alloy products high gloss processing.