Parameter:

Description | Parameter |

Models | GC2025-2H |

Working Area (X*Y*Z) | 2000*2500*300mm |

Max Moving Speed | 25m/min |

Max Engraving Speed | 20m/min |

Positioning Accuracy | 0.05mm |

Hold mode | T-SLOT & Clamp table |

Spindle Speed | 0-24000rpm/min |

Spindle Power | 4.5kw / 5.5kw air cooling spindle |

Tool Diameter | 2--12.7 |

Transmission | X,Y Axis High Precision Rack Gears, Z Axis Ball Screw |

X,Y,Z Guide rail | Linear Square Rail from Taiwan |

Control System | DSP controller |

Driving | Stepper motor |

Software | Ucancam / ArtCam/TYPE3/ powermill |

Command | G Code (plt, mmg, uoo, bmp) |

Voltage | AC380V/50-60Hz |

Gross Weight | 2000KG |

Net Weight | 1800KG |

Certificate | CE , CE test report |

Feature:

1. Whole machine is welded with seamless steel structure, with aging treatment.

2. Adopt Taiwan HIWIN high precision linear orbit.

X and Y axes adopt rack and pinion transmission, fast working, high efficiency .

Z axis adopts Germany and Taiwan ball screw,with high precision and long life time.

3. Well compatibility: CAD/CAM designing software e.g. Type 3/ Artcam/ Castmate/ Wentai etc.

4. With the function of re-carving after break point and power failure. Has the function of forecasting process time.

5. DSP or Original Nc Studio computer control system.

6. Perfect oil-inject system makes maintenance much easier.

7. Good duct-collect function and Considerate Oil plate to keep the table always clean.

8. We provide the DSP operating instruction in English.

Advantages :

1 .Welded structure by thick profiled steel stabilized under high temperature, ensures minimum distortion, excellent rigidity and powerful strength.

2. Japanese YAKSAWA servo motor makes the machine stable running with low noise, high speed and high accuracy.

3. Italy HSD spindle makes machine with high precision, long service time and stable movement.

4. Configured with carousel tool magazine of 12 tools, the machine can change tools speedy and freely.

5. Auto tool sensor enables the machine compensate the tolerance of the tool length.

6. High power suction vacuum pump, air-cooling, water-cooling or becker pump.

7. Taiwan SYNTEC control system, separated keyboard control, color LCD display, can alter the parameters and automatically change the tool .

8. Strong dust collector ensures site cleanliness during the machine operation.

9. Automatic lubricating system, one touch can finish periodic maintenance easily.

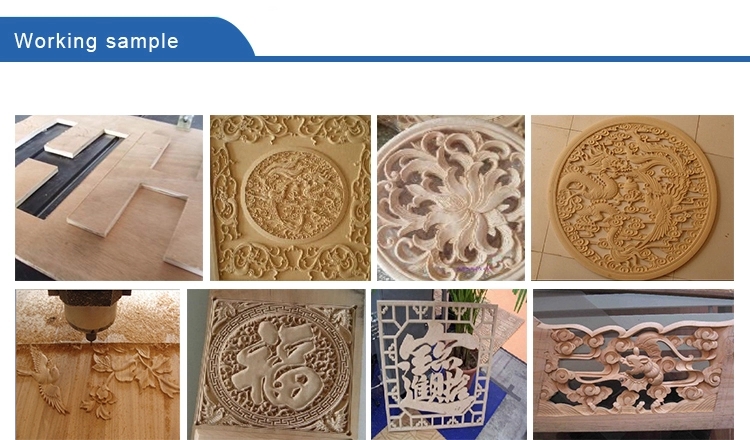

Application:

* Furniture: wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors and windows.

* The wood products: voice box, game cabinets, computer tables, sewing machines table, instruments.

* Plate processing: insulation part, plastic chemical components, PCB, inner body of car, bowling tracks, stairs, anti-Bate board, epoxy resin, ABS, PP, PE, PEHD and other carbon mixed compounds.

* Decorate industry: Acrylic, PVC,MDF, artificial stone, organic glass, plastic and soft metals such as copper, aluminum plate engraving and milling process.

wood coffin, aluminum EPS carving and cutting, door cabinet making, Cylindrical engraving.