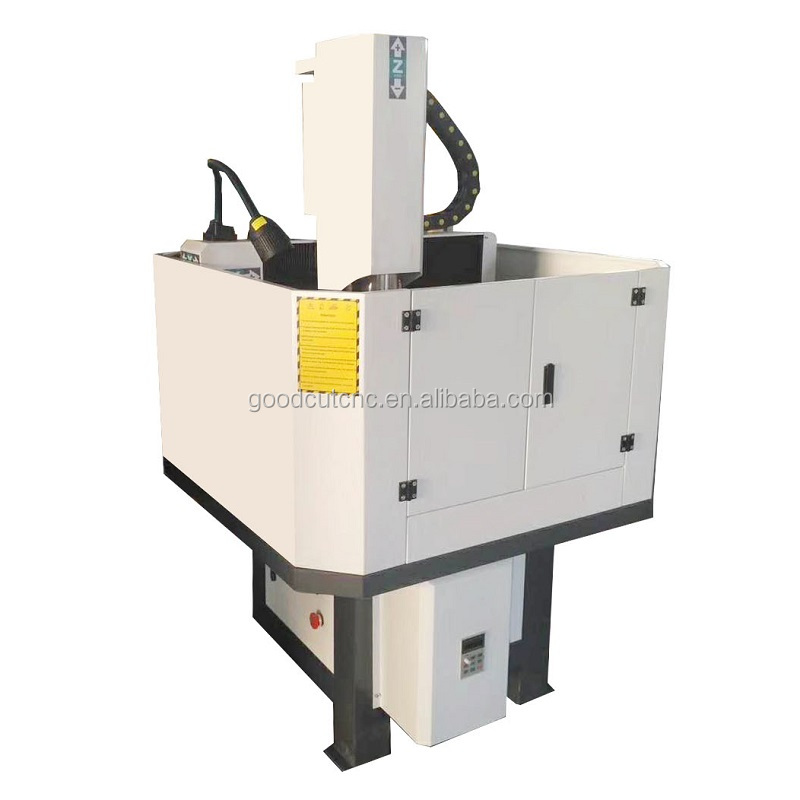

GC4040M Automatic CNC Metal Milling Machine for Sale at Cost Price

Automatic CNC Metal Milling Machine Features

1. The metal milling machine body is strong, rigid, high precision, reliable and durable. Whole steel structure, after high-temperature tempering, good rigidity and stability.

2. 3.2KW water-cooling spindle could keep working at low noise level, safeguarding stability for long-time operation.

3. High quality all steel linear guide with high precision,ensure machine frame much stability and durability.

4. The metal milling machine adopts advanced CNC system (NC studio or DSP control system), has break point memory mode to make sure continuous working after electronic drop or other postpone situation.

5. Professional high flexibility anti-bending cable, the number of anti-bending can be up to 70,000 times.

6. Automatic oil lubrication system is easy to operate by one key press, equiped with dust proof and water proof for XY axis, make the maintenance operation easily.

7. Imported high-precision ball screw gap, smooth movement, to ensure that the machine tools high-precision.

8. Using well-known domestic brands of water-cooled brushless spindle, low noise, strong cutting ability, to ensure the long time working.

9. Good three-axis and dust-proof structure to ensure that the machines longer service life.

10. High-performance driven motor to ensure that the machines high speed and accurancy.

11. Designer perfectly, select the best machine accessories, to minimize the failure rate preferred.

12. Breakpoint specific memory, power outages continued carving, processing time forecast, and other functions to ensure that accidental processing.

Parameter

Working area | 400*400*300mm 600*600*300mm |

Table | Integral cast iron countertop + hard grey PVC+ stainless steel water tank |

Spindle power | 2.2-5.5 Constant power water cooled spindle + water cooled

|

Motor and driver | Leadshine 750w servo motor and driver |

Control system | DSP A11 |

Transmission | TBR2505 high precision grinding ball screw from Taiwan |

Rail way | Taiwan HIWIN 20mm linear guide |

Inverter | 5.5kw Fuling inverter |

Wire | Built-in cabinet, Davos brand high flexible shielding cable, anti-electromagnetic interference,

Authentic Omron electronic point switch with filter, Chint electrical components. |

structure | Welded bed with square pipe, cast iron integrated gantry column, Feed height 300mm, integral cast iron table top.

|

Speed | 6000-10000mm/min |

Switch | Japanese OMRON Switch |

Oil system | Manual oil system |

Cover | The whole big encircle meal gold |

Coupling | High strength grinding coupling |

Others | 10 metal cutting knives, 2 sets of water pump, plus machine head lamp.

|

Advantages:

1) The machine body structure adopt cast iron, the rigidity is good, not easy to be deformed, to make sure the machine’s stability.

2) All axis with TBI ball screw transmission, ensuring the machine fast speed and higher precision.

3) Adopting Taiwan’s high-precision square linear guide, effectively imported the precision of carving.

4) Adopt high speed water cooling motor with invariably power, big torque, strong cutting, high-frequency and long-life.

5) Professional factory with DSP A11 control system, can provider good after sales service and technology support.

6) Good software compatibility, with machine ,we provider Artcam, Aspire, Powermill etc.

7) Available for continuous work for a long time.

Machine details:

2.2-5.5 Constant power water cooled spindle + water cooled

Welded bed with square pipe, cast iron integrated gantry column,

Feed height 300mm, integral cast iron table top.

Integral cast iron countertop + hard grey PVC+ stainless steel water tank

OMRON Switch

Applicable Industries:

Good at in processing all kinds of small workpiece ,widely used in advertising signs, badges, logo, mould construction equipment, mould products, industrial mold, etc.

Applicable Materials:

Suitable for all kinds of metal, such as copper, aluminum, iron, stell, stainless steel, alloy, also the acrylic, wood, MDF, double color board, stone, jade, ect.